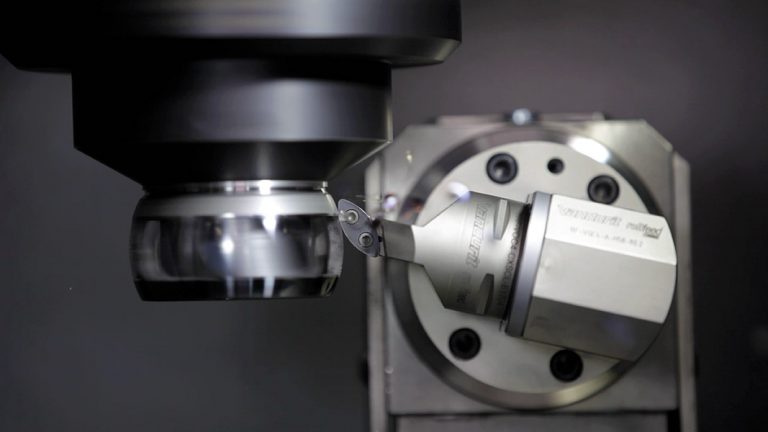

Soft turning with carbide |

rollfeed® | ISO | EFFECT | ||

| machining time | t | (sec) | 5 | 25 | = – 80% |

| feed (cumulated) | f | (mm/U) | 2,2 | 0,5 | = + 340% |

| cutting speed | Vc | (m/min) | 320 | 180 | = + 78% |

| cutting depth | ap | (mm) | 1,0 | 1,0 | ~ |

| surface quality | Rz | (µm) | 6,6 | 6,6 | ~ |

| material removal | Q | (cm3/min) | 705 | 141 | = + 400% |

Comparison to ISO turning

Machining data for different workpieces

Weichdrehen |

||||

| rollfeed ® | ISO | = | ||

| t | (sec) | 5 | 25 | -80% |

| f | (mm/U) | 2,2 | 0,5 | +340% |

| Vc | (m/min) | 320 | 180 | +78% |

| ap | (mm) | 1,0 | 1,0 | ~ |

| Ra | (µm) | 6,6 | 6,6 | ~ |

| Q | (cm3/min) | 705 | 141 | +400% |

Kugelgelenk |

||||

| rollfeed ® | ISO | = | ||

| t | (sec) | 9,5 | 18,7 | -49% |

| f | (mm/U) | 0,45 | 0,17 | +165% |

| Vc | (m/min) | 200 | 180 | +11% |

| ap | (mm) | 0,2-0,25 | 0,2+0,05 | ~ |

| Rz | (µm) | 1,0-2,44 | 1,0-2,5 | ~ |

| Q | (cm3/min) | 7,3 | 3,75 | +95% |

Zylinderlaufbuchse |

||||

| rollfeed ® | ISO | = | ||

| t | (sec) | 26 | 108 | -76% |

| f | (mm/U) | 1,8 | 0,6 | +200% |

| Vc | (m/min) | 200 | 200 | ~ |

| ap | (mm) | 0,5 | 0,5 | ~ |

| Ra | (µm) | 8 | 11 | +95% |

| Q | (cm3/min) | 208,4 | 50,2 | +315% |

Kugelkäfig |

||||

| rollfeed ® | ISO | = | ||

| t | (sec) | 4,6 | 46 | -90% |

| f | (mm/U) | 0,55 | 0,08 | +588% |

| Vc | (m/min) | 200 | 140 | +43% |

| ap | (mm) | 0,25 | 0,25 | ~ |

| Ra | (µm) | 0,35 | 0,35 | ~ |

| Q | (cm3/min) | 23,7 | 2,35 | +909% |

Deutsch

Deutsch