system components

Adaption of

01 rollfeed® Unit

rollFEED® unit “DirectDrive”

rollfeed ® unit „DirectDrive“ is driven by own servomotor. For

user-defined adaption into machine-tool (e.g. radial or axial onto

turret, tool-slide, console, etc.) rollfeed ® unit „DirectDrive“ in

turntable sizes 80mm / 125mm / 160mm comes with definition of

mechanical interfaces as well as user-

rollfeed® unit “TurretDrive”

Due to application and machine conditions rollfeed ® unit

„TurretDrive“ for lathes with powered tools and BMT interface is

supplied in turntable sizes 80mm and 125mm for radial adaption.

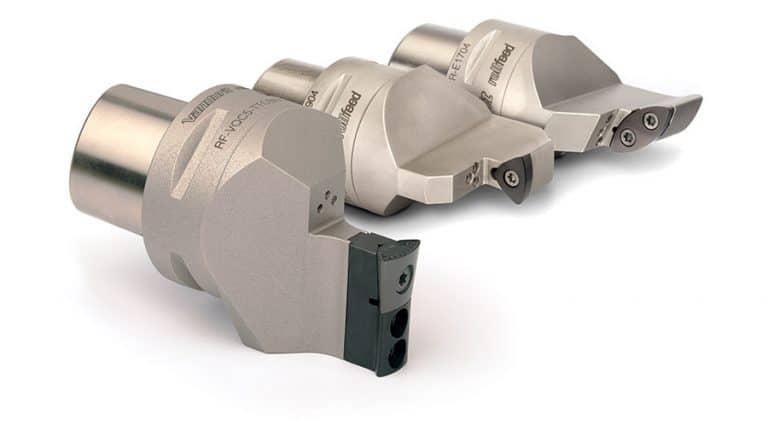

02 QuickChange (Capto) precision tool fitting

QuickChange (Capto) precision tool fitting

The tool fitting is mounted onto the rollfeed ® units turn table.

Depending on size of the turntable the tool fitting processes

quickchange (Capto) precision tool-holder of sizes 5, 6 and 8 (C5-C8).

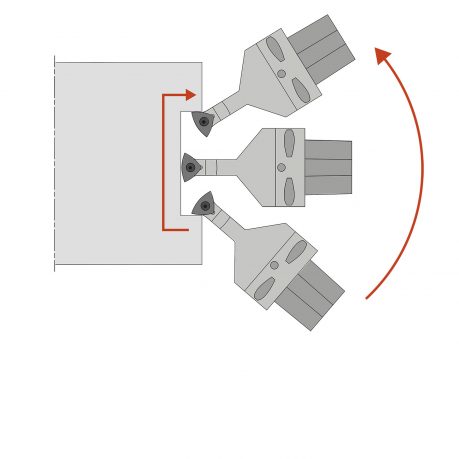

QuickChange (Capto) precision double tool fitting

With new product innovation rollfeed ® double tool fitting VQCF2 you can use one rollfeed ® unit for two different applications, for example rollfeed ® turning and ISO grooving.

You don’t need a second tool place on the turret and there is no need and time loss with changing tools. The new rollfeed ® double tool fitting VQCF2 is the next step in evolution of productivity.

03 QuickChange (Capto) precision tool holder

QuickChange (Capto) precision tool holder

quickchange (Capto) precision-tool-holders are equipped with particularly

designed pockets for rollfeed ® inserts.

04 rollFEED® tools

rollfeed® inserts

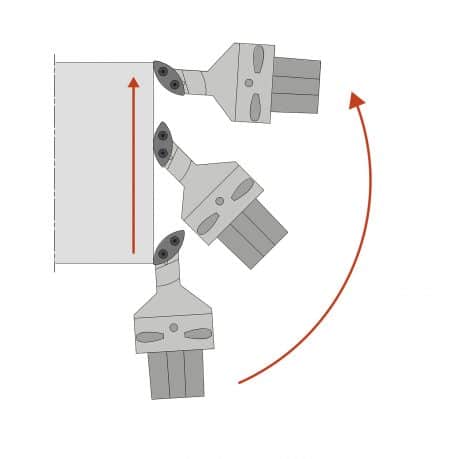

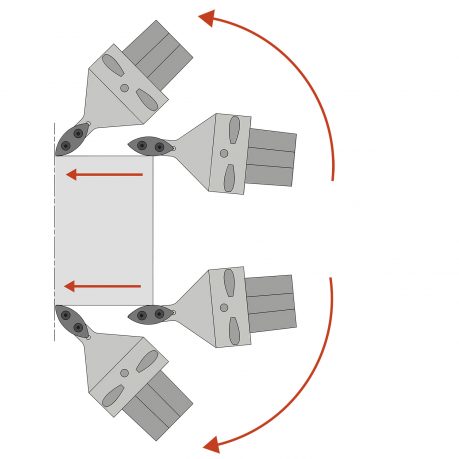

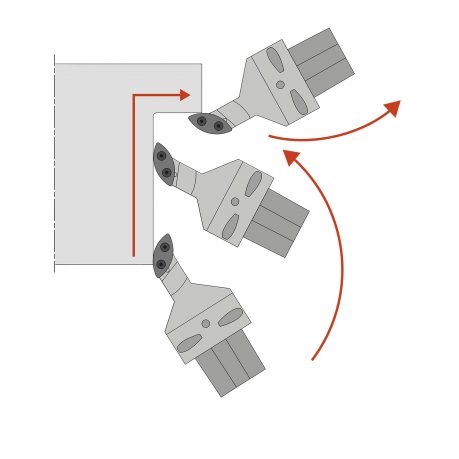

Unique rollfeed ® insert geometries machine up to three different workpiece

sides – in one motion.

Deutsch

Deutsch